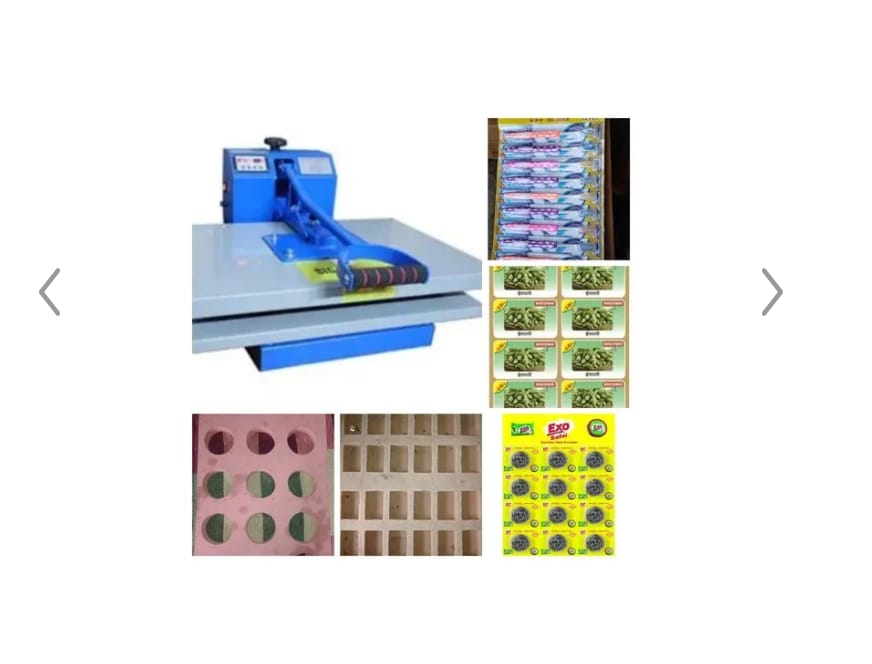

A scrubber sealing machine is a piece of equipment used in the manufacturing process of scrubber pads or sponges. These machines are designed to seal the edges of scrubber pads, ensuring durability and preventing fraying. Scrubber pads are commonly used for household cleaning purposes, and sealing their edges enhances their lifespan and usability.

Here are some key features and functions typically found in scrubber sealing machines:

-

Sealing mechanism: Scrubber sealing machines use heat to seal the edges of the scrubber pads. They often have heated elements or rollers that melt the edges of the pad material, creating a sealed edge that prevents unraveling and fraying.

-

Adjustable temperature and pressure: The machines usually feature adjustable temperature and pressure settings to accommodate different types of scrubber pad materials and thicknesses. This flexibility ensures proper sealing without damaging the scrubber pad.

-

Conveyor system: Scrubber sealing machines may include a conveyor system to feed the scrubber pads through the sealing process continuously. This allows for efficient production and consistent sealing quality.

-

Cooling mechanism: After the sealing process, some machines may have a cooling mechanism to quickly cool down the sealed edges, ensuring that the pads are ready for further processing or packaging.

-

Safety features: To ensure operator safety, scrubber sealing machines may incorporate safety features such as guards and emergency stop buttons to prevent accidents during operation.

-

Speed and capacity: These machines come in various sizes and capacities to accommodate different production requirements. Some machines are designed for small-scale or batch production, while others are suitable for high-volume industrial production.

-

Ease of maintenance: Maintenance is essential for keeping the machine in optimal working condition. Scrubber sealing machines may feature easy-to-access components and straightforward maintenance procedures to minimize downtime and ensure consistent performance.

Investing in a scrubber sealing machine can streamline the manufacturing process of scrubber pads, improving efficiency and product quality. It's essential to select a machine that meets your production needs and provides reliable sealing performance for your specific scrubber pad materials. Additionally, proper training for operators and regular maintenance will help maximize the machine's lifespan and productivity.