A long cotton wick making machine is a specialized device used in the production of long cotton wicks, which are commonly used in various religious rituals, ceremonies, and traditional lamps. These machines are designed to automate and streamline the wick-making process, allowing for efficient and consistent production on a large scale.

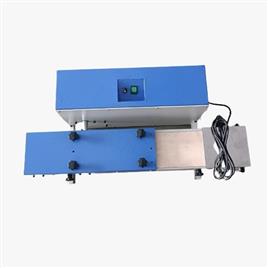

Typically, a long cotton wick making machine consists of several components, including a cotton feeding mechanism, a wick-forming unit, and a cutting mechanism. Raw cotton is fed into the machine, where it undergoes processes such as cleaning, carding, and twisting to form a continuous wick. The wick is then shaped and cut to the desired length before being collected or packaged for distribution.

Some advanced long cotton wick making machines may include features such as adjustable settings for wick thickness, length, and density, allowing manufacturers to produce wicks according to specific customer requirements. Additionally, these machines may incorporate safety features and automatic controls to ensure smooth operation and minimize downtime.

Long cotton wick making machines are essential for manufacturers seeking to increase productivity, reduce labor costs, and maintain consistent product quality. By automating the wick-making process, these machines help streamline production operations, improve efficiency, and meet the demands of the market for high-quality cotton wicks. Overall, long cotton wick making machines play a crucial role in the traditional and cultural practices where cotton wicks are used.